Machinery Foundation Bolts & Spherical Washers

From our experience, often very little consideration is given to foundation bolts for highly dynamic machinery such as reciprocating compressors/engines, stamping, forging and crushing equipment.

This coupled with insufficient mass in the foundation, often leads to higher than desirable vibration levels, which in turn can cause cyclic stresses in anchor bolts and untimely stress cracks and bolt failure.

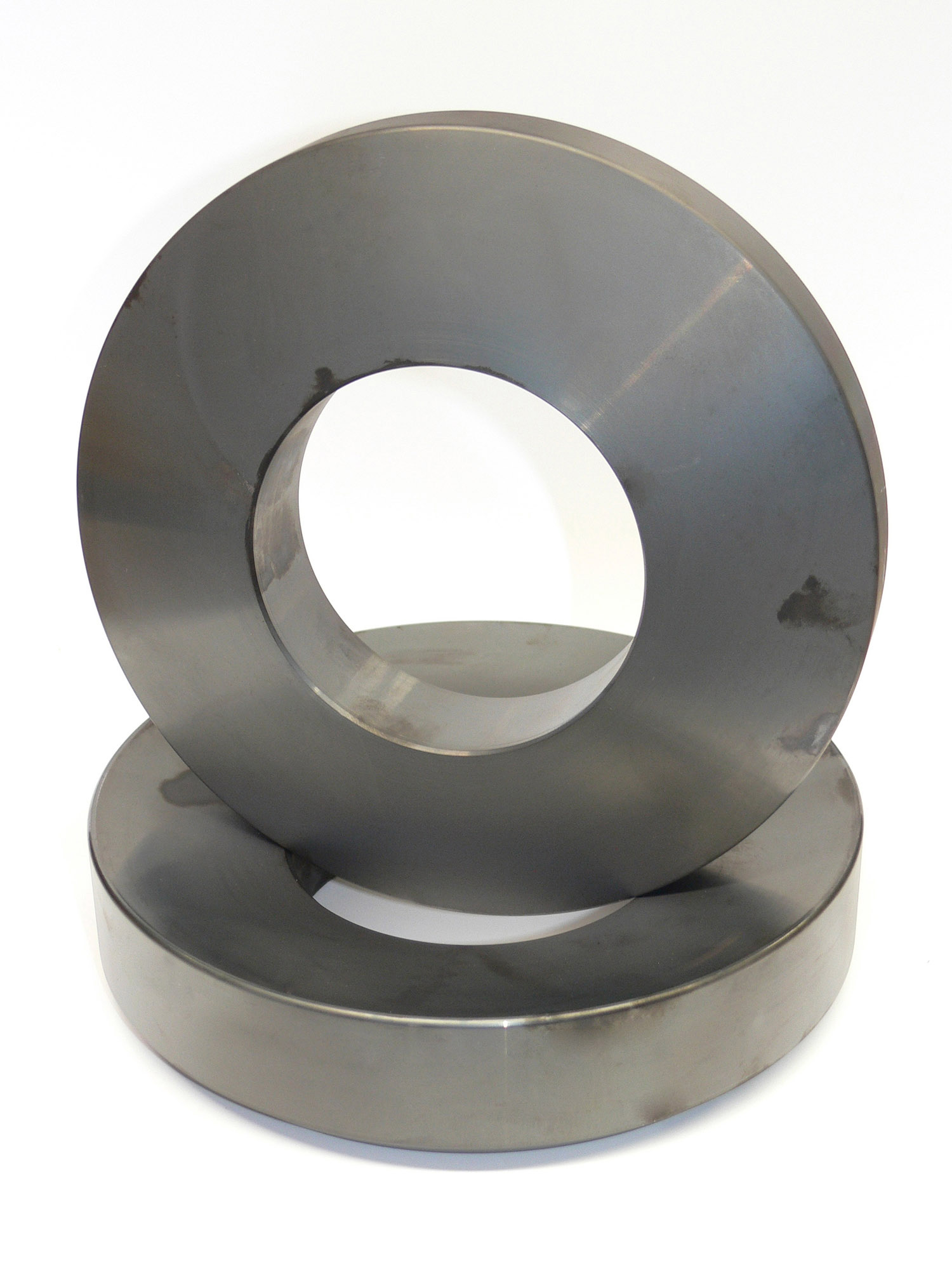

Other problems can include and be as simple as misalignment between the axis of the foundation bolt and the contact area below the anchor bolt nut. This results in a bending movement in the thread root directly below the nut which leads to short radius fractures developing, and ultimately bolt failure.

Many of these problems can be resolved in both new and existing installations through careful design of the anchoring system. In complex situations we work with our finite modelling/Space Gass partners to calculate or measure the forces to be contained. From there, with real online data, we can design an anchor bolt solution that accommodates these forces by ultimately allowing the dynamic energy developed during machine operation to be distributed into the foundation and surrounding soil or bedrock.

ESI Alphatec have supplied bolts up to M115mm x 5.8m including all associated spherical washer hardware and hydraulic tensioning and monitoring systems.

Critical installations can incorporate live preload measurements to provide warnings when preload drops below defined values. These systems can also be used for quality purposes during installation ensuring the bolts are always at the correct tension.

Please get in touch with our team to discuss your requirements.